SF2

A Non-Traditional Stabilization System for Township Roads, Remote Access Roads and Pads

Traditional approaches to building and stabilizing unpaved remote access roads and pads can be temorary and costly because gravel sources are scarce, making local readily available silts, sands and low plasticity fine-grained soils the perfered constuction material.

That’s why Midwest developed SF2®.

Midwest's SF2 Builds Stronger, More Durable Pads and Roads Constructed with Locally Available Soils and Advanced Chemisty

SF2 is a synthetic fiber and synthetic fluid road stabilization system that enhances compressive strength, CBR, shear strength and material adhesiveness.

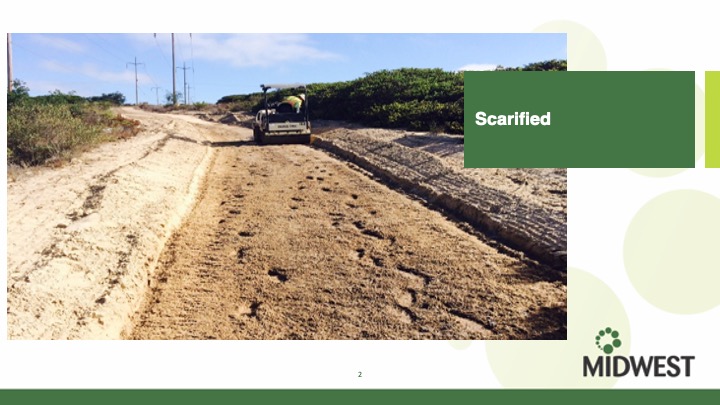

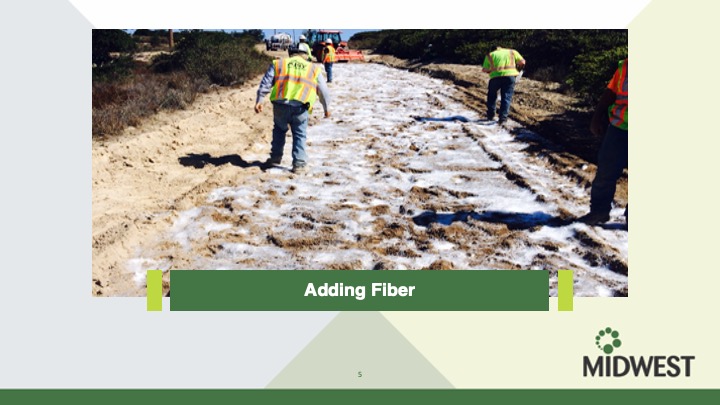

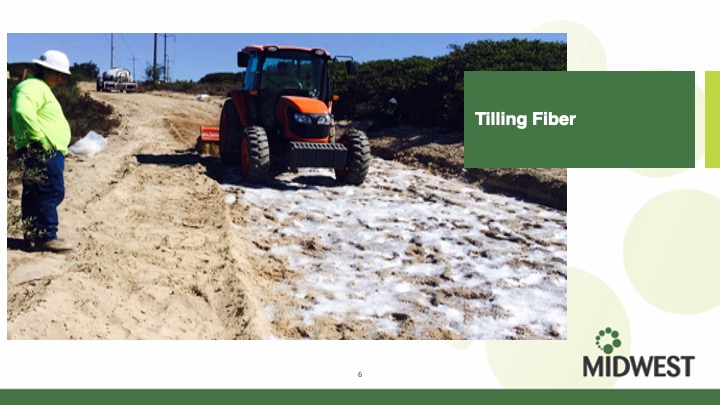

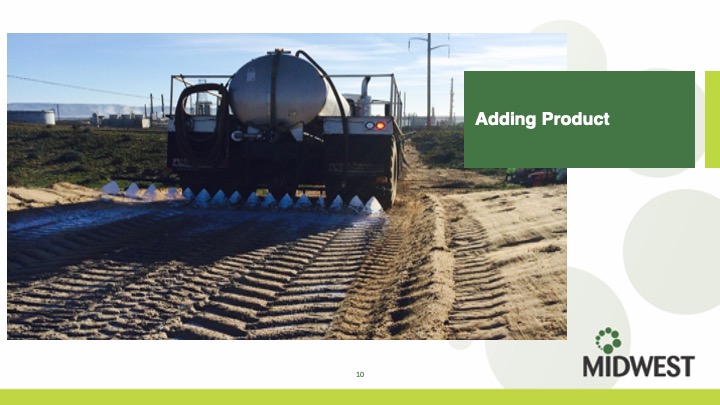

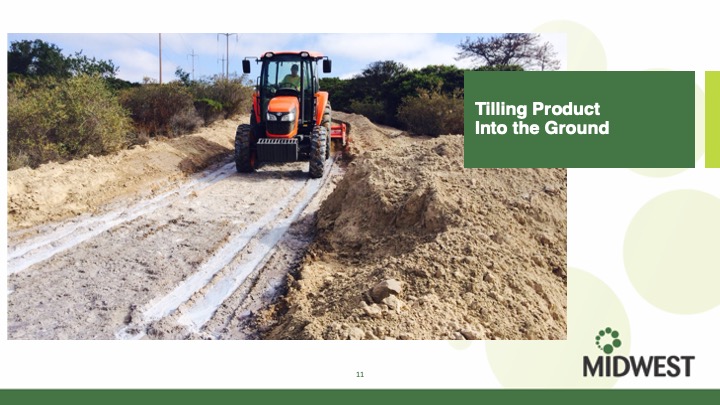

It does this through advanced nanotechnology that binds native soil together at the molecular level. First, a layer of synthetic fibers is laid down on the road surface. Then, the SF2 synthetic fluid is layered on. The fluid is engineered to coat and load each soil particle which, together with the SF2 fibers, creates a matrix that can withstand extreme traffic loading. The fibers and fluid are then blended into the in situ soil or placed aggregate to a depth of six inches. This means that culverts or underground utilities won’t be disturbed.

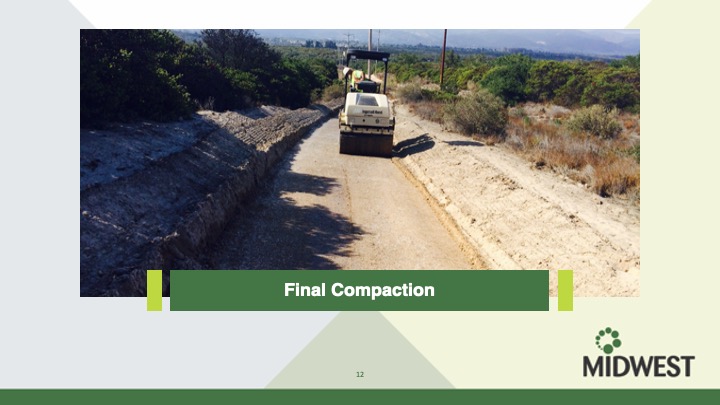

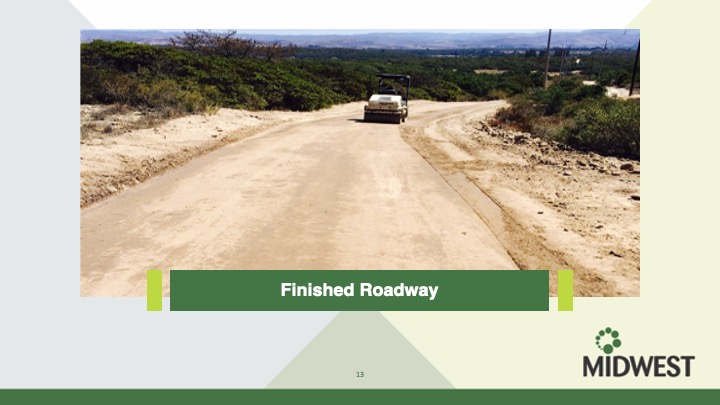

After grading and compacting the blended mix of SF2 and soil to the designed density, a final topcoat of SF2 liquid is applied, which can be followed by a stone wear course. The road is then immediately ready for traffic.

This unique binding action allows the road to grow in compressive strength over time, with heavy traffic usage.

In addition, roads stabilized with SF2 are water-resistant and, unlike Portland cement, impervious to freeze-thaw cycles. All of this means less maintenance, fewer and easier repairs, lower lifecycle costs and fewer delays to the movement of your supplies, material and equipment.

“I was somewhat surprised in that the pad surface actually was more hardened after winter breakup this past year. That has to be due to the aging process of the synthetic fluid binder material.” – Mike Matteucci [Program Consultant] (18 months after application of SF2)

GOOD FOR:

BENEFITS

Midwest's SF2 Takes the Hassle Out of Road Managment Utilizing Local Materials While Reducing Your Costs

- Increases CBR up to 80% in 48 hours, and 400% with traffic in 30 days

- Improves shear strength

- Gains strength for up to two years

- Keeps road and pads intact despite rain and thaw events

- Does not break down, thereby eliminating muck and costly repairs reduces road and pad maintenance

- Allows traffic to continue during reconstruction to keep your operations moving

- Can be installed year-round, providing you ultimate application versatility

- No cure time, unlike Portland cement

- Uses local soil, with no non-native aggregate needed

- Can accommodate chip seal, aggregate or asphalt surfacing

TRADITIONAL METHODS, LIKE IMPORTING AGGREGATE, QUALITY SOILS OR PORTLAND CEMENT ARE COSTLY

They add to delays and maintenance costs.

Aggregate

- Expensive to bring in from an outside source

- Uses up trucks and clogs roads that could be used more productively

- Fines (particulate matter that binds aggregate together) are lost as dust in dry weather and get washed away in wet weather

- Reduced fines allow gravel and larger aggregate to come loose, damaging vehicles and washing away from the road

- This creates potholes, ruts and, during inclement weather, thick muck that traps and slows down trucks.

- Requires regular maintenance, which increases costs and delays

Portland Cement

- Can’t be installed during the winter, potentially creating delays

- Prone to breaking up during freeze-thaw cycles

- Requires costly excavation to repair

- Has a cure time of 4-7 days, creating delays

MIDWEST'S SF2 IS THE SOLUTION FOR TOWNSHIP ROADS, REMOTE ACCESS ROADS AND PADS UTLIZING MARGINAL SOILS OR LOCAL MATERIALS

SF2 builds stronger, more durable roads that are weather-resistant and easy and affordable to maintain and repair. It creates the lowest total cost of ownership for road maintenance budgets. And, like all Midwest products it also protects the environment. (SF2 is certified safe for human, animal and plant life by the EPA’s Environmental Technology Verification program.)

At Midwest, we don’t just make claims. We prove them. Below, you can find third-party test reports, case studies and other documents proving SF2’s performance.

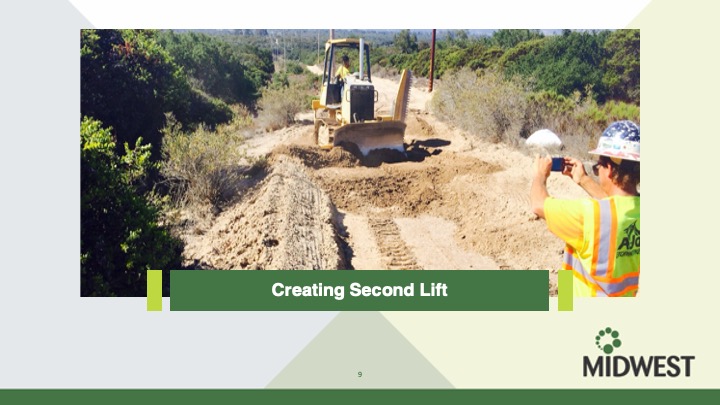

SF2 INSTALLATION VISUAL PROJECT SUMMARY WITH SOIL-SEMENT ENGINEERED FORMULA AND FIBERS

BUILD STRONGER ROADS. FILL OUT THE FORM TO BEGIN THE PROCESS.