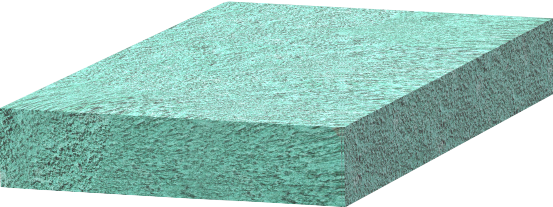

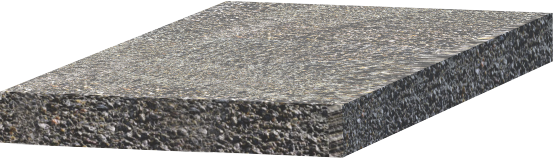

Midwest takes a wholistic approach to road stabilization. Often times the base and surface are mistakenly viewed as independent pavement layers. Although both layers serve a unique and different fuction, their perfomance and servicabilty is very much connected to each other. For instance, a well-constructed surface course is likely to fail prematurely if the base course is not adequately constructed and/or stabilized. The same is true about a well-constructed base course with a poor surface.

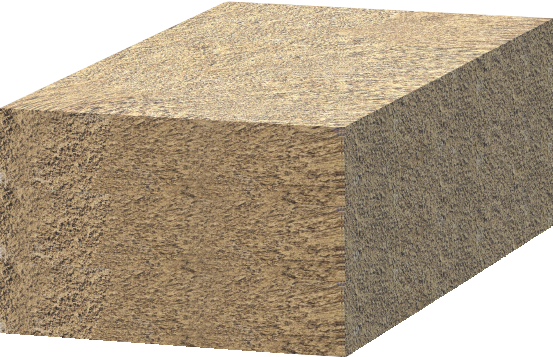

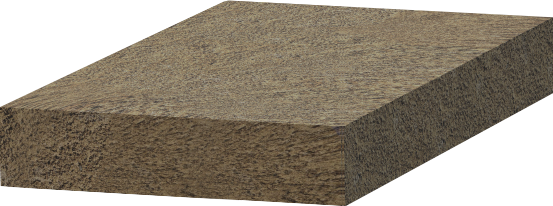

Our NaturalPave Road Stabilization is strategically designed to improve the two main components of a roadway: the base and the surface. However, the NaturalPave Base Stabilization does not require surfacing and can act as its own wear course layer when additonal surface protection, traction, and wear resistance is not required.