Midwest is your best choice to co-develop a winterization program for your railway. As the leading third rail anti-icing and deicing system — with more than 37 years of experience applied to each customer need — Midwest chemists, engineers and application experts are always pushing the envelope to develop cutting-edge processes, products and services; stay on top of the learning curve; and educate our customers for our mutual success.

Unlike other companies, Midwest has our own lab, so developing new solutions is business as usual. We also manufacture our own spray systems and other equipment to ensure optimal application, and remain fully committed to safety (with plenty of awards to show for it), while protecting the environment.

Midwest carries more patents and certifications than anyone in the industry, guaranteeing unparalleled results. And we’ve been specialists in railway winter protection products and systems for four decades:

1978 —– Ice Free Switch and Switch Treator applicators are introduced for anti-icing railroad switch plates.

1988 —– CTA partners with Midwest to supply third-rail anti-icers

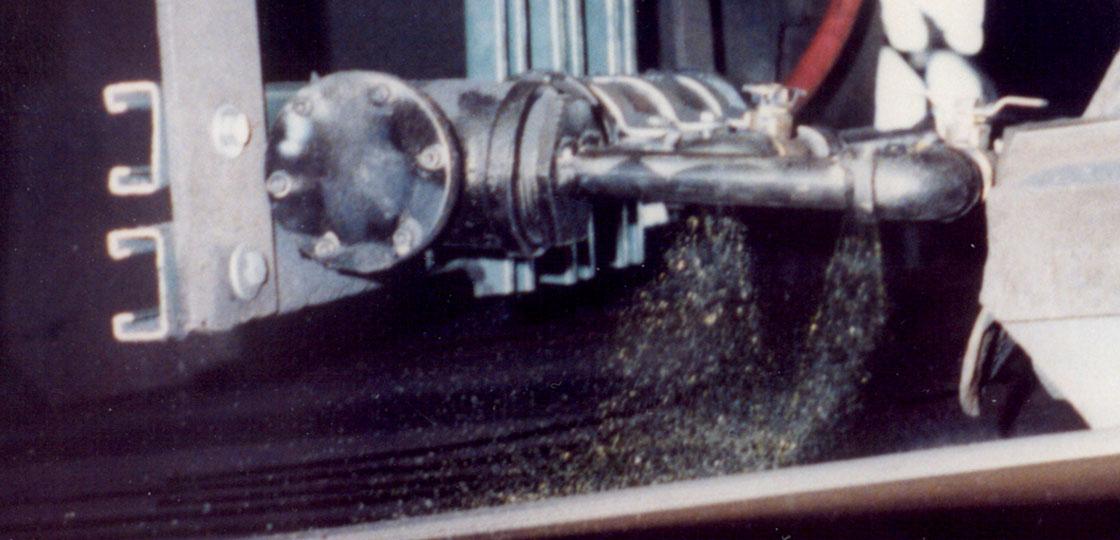

1999 —– Expansion into the Rail and Transit market with Zero-Gravity Third Rail Anti-Icer featuring NASA technology

2002 —– Ice Slicer Third Rail Spray Systems are introduced to mass transit for application of third rail anti-icing

We’re also the most trusted in the business. Midwest serves as approved supplier for these railroads:

Burlington Northern Santa Fe | CSX | Canadian National | Canadian Pacific | Norfolk Southern | Union Pacific

As well as short-line and regional railroads, along with industrial facilities, with current Zero Gravity Third Rail® customers including:

Washington Metro Area Transit Authority (WMATA) | Maryland Transit Authority (MTA) | Bombardier (JFK International) | Metropolitan Atlanta Rapid Transit Authority (MARTA) | Long Island Railroad (LIRR) | South Eastern Pennsylvania Transportation Authority (SEPTA) | Chicago Transit Authority (CTA) | Metro Boston Transit Authority (MBTA) | Port Authority Transit Corporation (PATCO) | ProTrans BC — Canada Line