Leading technology and innovation for the world’s most effective Fines Preservation

Fines Preservation

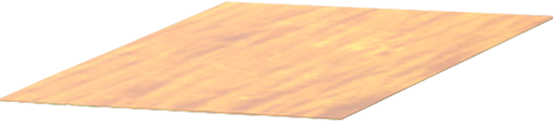

Fines Preservation is a surface stabilization technique that prevents the loss of fines and aggregate from newly rehabilitated or well-maintained runways by proactively locking them into the runway surface. Fines Preservation is achieved by topically applying one of Midwest’s high-performing synthetic fluid and binder systems to a prepared gravel runway surface to create a bound runway surface to a depth of 2”. This proactively preserves the aggregate and fines, improves the overall runway performance, and lowers the life cycle costs by extending the gravel life and reducing maintenance requirements.

A

B

C

A

Topically Applied EK35 or EnviroKleen

Creates a bound, FOD free surface with improved performace, durability and longevity.

B

Prepared and Compacted Aggregate Surface Course

C

Subgrade

Unlike dust palliatives that wash out of the surface, Fines Preservation products build ground inventory therefore annual or biennial maintenance applications require a fraction of the volume of product initially applied. The cost savings realized from the preservation of the runway’s fines and aggregate alone will allow critical resources to be used to address previously deferred maintenance needs.

This is the method of choice for existing gravel runways pursuing a simplified application with improved performance, longevity, and maintenance cost savings benefits not realized with temporary dust palliatives. Midwest has successfully implemented Fines Preservation on over 100 unpaved runways across Alaska and Canada over the last two decades.

EK35

EK35 is a patented technology made from synthetic fluid enhanced with a binder system. EK35 was developed through years of research and testing to create a solution that is both high performance and eco-friendly. When installed, EK35 creates a bound runway surface that results in improved performance, longevity, safety, and stabilization. An EK35 stabilized runway provides year-round consistent accessibility by eliminating seasonal soft spots, harmful moisture infiltration, and freeze/thaw damage. This is critical to northern regions that are constantly combatting the effects of climate change and experiencing less “frozen” months and more summer months. As aircrafts equipped with gravel kits are being removed from service and as Dash8/Q400s and jet traffic are being introduced, EK35 becomes the ideal and only solution for remote northern gravel runways.

Immediately after topically applying EK35 to the prepared gravel runway surface, the EK35 begins penetrating the compacted surface to a depth of approximately 2''. As the EK35 penetrates, it uniformly coats all aggregate particles with its adhesive agent. The binder then physically bonds permanently to the particles as a result of a chemical reaction. This adhesion to each soil or aggregate particle, and then the binding of all separate particles together, creates a stabilized surface course. Over time, traffic loading further tightens the surface using cohesion and adhesion mechanisms, thus increasing the CBR value, performance, and longevity of the runway.

Water creates many adverse effects for cold region gravel runways and is a main factor behind gravel runway performance deterioration and unsafe operating conditions. Improper surface drainage, moisture infiltration and freeze/thaw damage results in:

- Reduction of shear and bearing strength

- Freeze/thaw expansion and contraction damage

- Stripping of some stabilizers and dust palliatives

- Surface erosion and removal of unbound fines

- Reduction in service life

- Destabilization of the designed base course

- Increased maintenance activities

- Seasonal soft spots, deformation, rutting, potholes, and water pooling

One of the most important functions of any surface layer is to prevent moisture infiltration into the underlying base course by creating a tightly bound surface that repels moisture and facilitates the drainage of water away from the runway. Incorporating EK35 into the aggregate surface has been proven to:

- Maintain improved CBR values when exposed to excessive moisture

- Retain performance and mechanical properties during freeze/thaw

- Resist moisture infiltration and improve surface drainage

- Repel water (not be soluble in water)

- Remain adhered to aggregate particles in wet conditions and exhibit very limited leaching

Ultimately, an EK35 stabilized runway provides year-round aircraft accessibility by eliminating seasonal soft spots, harmful moisture infiltration, and freeze/thaw damage. This is critical to northern regions that are constantly combatting the effects of climate change and experiencing less “frozen” months.

EnviroKleen

EnviroKleen® is a patented, two-part system consisting of a synthetic fluid and the KleenBinder® viscoelastic polymer binder. EnviroKleen is the ideal solution for runways seeking a completely environmentally friendly solution without sacrificing performance.

EnviroKleen is specifically designed to offer a safe, effective, and environmentally friendly solution that can be used in the most sensitive ecosystems without damaging effects to the surrounding environment. Using EnviroKleen helps conserve resources like water and energy, and it prevents contributions to air, water, and land pollution. The positive environmental impact of EnviroKleen has been demonstrated and proven by the most prominent environmental agencies of the United States and Canada, including the US EPA, the United States Geological Survey (USGS), the US Army Corps of Engineers, and the Bureau de Normalization de Quebec (BNQ).

EnviroKleen’s synthetic carrier fluid permeates deep into individual aggregate and soil particles but the powerful KleenBinder intertwines and becomes entangled on the exterior of the particles. This phenomenon causes a high concentration of KleenBinder to accumulate on the particle surfaces, which activates the polymer design features. The large molecular weight and high viscosity of the KleenBinder creates powerful adhesive and cohesive forces that lock the soil particles together into a durable, bound runway surface.

EnviroKleen Certifications, SDS, Brochure, and CBR Design Curve

WANT THE MOST ADVANCED GRAVEL RUNWAY TECHNOLOGY IN THE WORLD?