Midwest will work with you and your team to co-develop a customized dust control program especially designed for iron and steel mill roads and your needs. Since Midwest does not rely solely upon products, but instead relies on a program based on both product and application strategy, critical knowledge is gathered in order to understand traffic flows, traffic loading, spillage, track-on and contamination sources. This is done during our initial site evaluation and continues throughout the program.

Your program is co-developed to eliminate the costs of watering, grading and repair; improve the road running surface (no potholes or washboarding); improve the health and safety of employees; and maintain air quality compliance. All of this translates into greater productivity.

In one example, Midwest worked with one of the largest steel producers in the United States to save nearly half a million dollars, directly improving its bottom line while reducing dust by 90%. All this translates to a lower cost per square foot.

Go from “dust problem” to “dust control solution” with Midwest. Your operational reality is that massive clouds of dust around your huge network of roads damages equipment, undermines production and negatively affects employee morale. Whether it’s employees or contractors, you’re paying someone to replace, repair and clean equipment and parts. That means they aren’t producing salable goods and that means you are diverting equipment and manpower to unproductive efforts.

Together with Midwest, you can change that reality — in order to control dust, control investments in time and money for watering and repair; and control the structural integrity of your steel and iron mill roads and lots.

In addition, Midwest science has created products that are environmentally friendly, sourced from sustainably produced materials and fully compliant.

COMPREHENSIVE MANAGED SERVICE PROGRAM

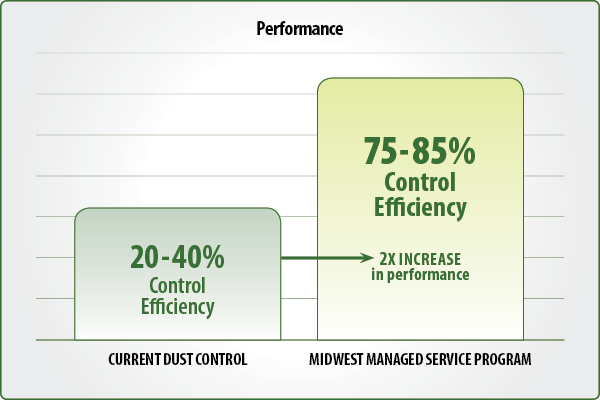

A full program, rather than reliance on product alone, in which Midwest co-develops a plan and provides application services as well as monitoring.

CUSTOMIZED SELF-APPLICATION PROGRAM

Midwest co-develops a program with you, and you use your own personnel and equipment for application.

DUST CONTROL ENGINEERING AND COMPLIANCE SERVICES

Midwest uses engineering, science-based models to confirm, document and prove levels of compliance.