Total performance with none of the asphalt.

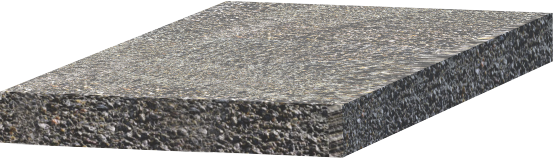

Midwest NaturalPave delivers the structural strength of asphalt at only 40% of the construction cost. You save up to 60% of that cost, while replacing 100% of the petroleum used in conventional, flexible pavement construction. This is a considerable step forward, because more than 95% of pavements are asphalt. This is critical because asphalt prices are considered volatile in nature, making project planning and budgeting daunting tasks.

Asphalt is also made to fail. Its main failure mode is cracking, with a potential that increases over time due to the age hardening of the asphalt binder — a natural aging process of the material. According to the Asphalt Institute, “Pavement distresses accumulate as asphalt pavements age and traffic pounds them. If timely maintenance isn’t performed, distresses are compounded. Cracks become potholes and potholes become craters.”

Other complications to a continued reliance on asphalt binders are increased environmental regulations; rising costs of asphalt binder; and modifications to the crude petroleum refinery process, implemented to garner more petroleum fuel while reducing asphalt residue.

Get maintenance costs under control, too.

Maintenance is a cost that never ends. And unless you want to incur greater costs and greater inconvenience, it must be performed frequently. According to Larry Galehouse, director of the National Center for Pavement Preservation (NCPP), “We have to do road maintenance when the roads are in fair-to-good condition, rather than waiting until they are in poor condition.”

Worse, maintenance is needed when it is most costly and difficult. That’s why the Asphalt Institute’s publication states that the less-than-optimal choices in inclement weather or emergency situations are the throw-and-roll method (with material compacted with a hand tamper or the truck tires) or throw-and-go (with no compaction at all — relying solely on the moving traffic to do so!).